The global high temperature coatings market is expected to reach USD 4.74 billion by 2024, according to a new report by Grand View Research, Inc. Surging thermally efficient coatings requirement that can protect industrial and commercial equipment in moderate to extreme temperature conditions is expected to drive industry growth over the next eight years.

Technological innovations and significant R&D spending by key industry participants regarding commercializing single-component coatings for multiple applications is anticipated to stimulate market growth over the forecast period. Companies have been constantly involved in developing finished products which can be used for wide range of operating temperatures ranging from 150 degrees Celsius to 750 degrees Celsius in addition to providing corrosion resistance.

High temperature coating demand in cookware is anticipated to emerge as fastest growing end-use segment over the forecast period. In terms of demand, the sector is expected to grow at a CAGR of 5.5% over the forecast period.

/image%2F6144638%2F20201216%2Fob_3fce76_high-temperature-coatings-market.png)

View exclusive Global strategic Business report

Major appliances such as bakeware, induction appliances, and food processors have gained significance in commercial and residential sectors. This segment has witnessed significant growth in France, Japan, and South Korea owing to growing awareness towards innovative cooking technologies that sustain the nutrient levels of the food.

Further key findings from the report suggest:

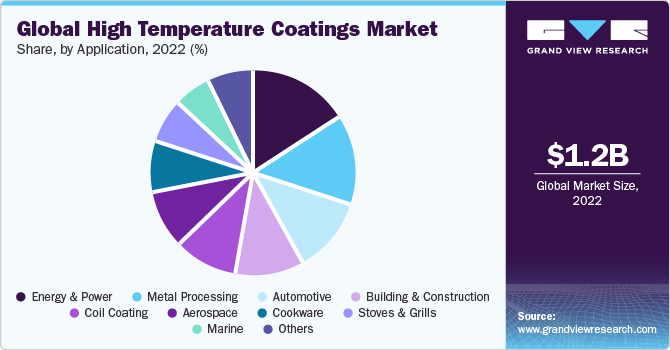

- The global high temperature coatings market demand was 1,009.9kilo tons in 2015 and is expected to reach 1,444.1 kilo tons by 2024, growing at a CAGR of 4.1% from 2016 to 2024

- Acrylic was the leading product segment and accounted for 23.3% of global high temperature coatings revenue in 2015.The segment is anticipated to reach a net worth of USD 1,117.1 million by 2024.

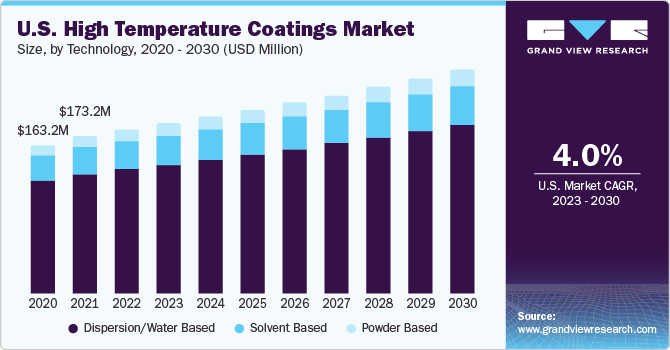

- Powder coating is anticipated to witness the highest growth over the forecast period. The segment is anticipated to grow at a CAGR of 5.4% in terms of demand from 2015 to 2024.

- The energy & power sector emerged as the leading high temperature coating end-use segment and accounted for 16.4% of total demand in 2015. The segment is expected to reach a net volume of 34.7 by 2024 in the U.S.

- Asia Pacific was the major high temperature coating market and was valued at USD 1,174.8 million in 2015. The region is also expected to witness the fastest growth rate over the forecast period.

- Key players operating in the global industry include BASF, PPG Industries, Sherwin-Williams, Axalta Coating Systems, Jotun AS, and AkzoNobel NV. Major strategy adopted by the global players includes sourcing of raw materials at low cost thereby enhancing their profit margin and gain competitive edge over other industry participants.

To understand key trends, Download Free Sample Report

However, lack of synergy among building codes in different countries is expected to hamper market penetration in the construction sector. Consistency in regulatory norms enables coating manufacturers to enhance their investments in R&D projects. Underwriters Laboratories (UL) is a major regulatory agency that has issued guidelines and standards for conducting application testing of the coatings.

Other government and regulatory agencies such as ASTM, ANSI, ISO, and NFPA govern the testing and formulation of ingredients used in the coatings. Incidents of building collapse and occupational injuries due to fire have led to numerous revisions in the safety norms to integrate the flame retardant inorganic agents in coating materials. Silicone, phosphorus, and halogen-based products have gained significance owing to their enhanced resilience to high temperature environment.

Acrylic emerged as the largest product segment and accounted for over 20.0% of the total volume in 2015. Surging demand for heat resistant coatings with decorative properties in building and transportation infrastructure has led to high penetration of the acrylic based products in various industries. Low volatile organic compound (VOC) content in the product formulation is another factor contributing to its increased adoption in the industries.

Polyethersulfone (PES) is expected to emerge as the fastest growing segment in terms of volume over the next few years. The product is estimated to reach over USD 470.0 million by 2024. Increasing product demand can be attributed to its physical characteristics such as enhanced metal adhesion, transparency, and long-term thermal stability. These features have increased the product usage in a broad range of applications including wood furniture, construction, automotive refinishes, and marine.

Epoxy was the second largest segment in 2015 owing to its high durability and chemically resistant characteristics. The segment is expected to expand at a CAGR of over 4.0% in terms of revenue and volume during the forecast period. Epoxy-based products find extensive usage in corrosion resistant applications including automobiles, boats, steel pipes, and transmission pipelines, which are exposed to high temperature environment. Demand for epoxy based coatings is increasing due to their compatibility with a wide range of color formulation and solvent free ingredients.

Energy and power was the leading end-use segment in 2015, accounting for 16.4% share of the total revenue. Equipment such as furnaces, heaters, towers, and ducts used in refinery and chemical plants are exposed to heat and high temperature environment. Growing concerns over equipment durability and downtime are expected to drive the demand for heat resistant coatings with enhanced color stability and corrosion resilience.

In 2015, metal processing emerged as the second largest segment in terms of revenue. Increased adoption of the product can be attributed to surging demand for metal equipment in the industrial and commercial sectors that can withstand rusting due to external weather. Metal piping, heavy equipment, and industrial machinery find usage in various applications such as forestry, agriculture, manufacturing, and waste treatment facilities. Growing concerns over equipment corrosion and degradation are expected to drive the segment over the forecast period.